Β”-Alumina

β”-alumina (rhombus: R3m) and β-alumina (hexagonal system: P63/mmc) are the two different crystal structures. The chemical composition of β-Al2O3 and β”-Al2O3 and the stacking sequence of oxygen ions between ionic conductive layers are different, β-alumina is Na2O·(8 ~ 11)Al2O3, β”-alumina is Na2O·(5 ~ 7)Al2O3, β-alumina is 2 spinel accumulation, β”-alumina is 3 spinel accumulation. The ionic conductivity of the beta phase is higher than that of the beta phase because it contains more Na+. As a traditional sodium ion conductor material, NA-β′/β”-Al2O3 is widely used in the membranes and electrolytes of Na/S batteries and solid sodium ion batteries. At present, our company can provide with two grades of β”-alumina products, B-D2 and BM-D2.

Download documents

Single Crystal Alumina

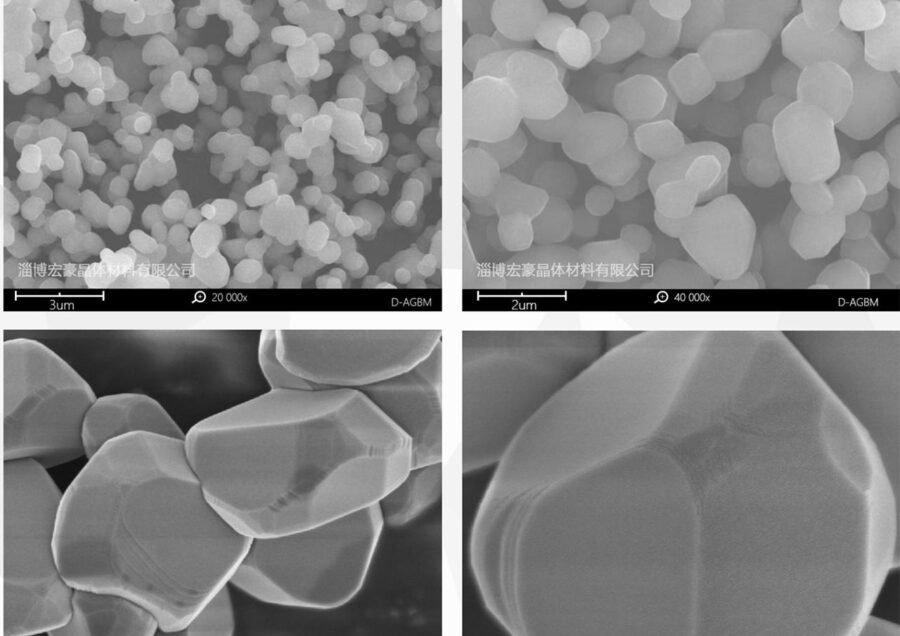

Single Crystal Alumina is easier to form thermal conductivity channel by the line contact and surface contact because heat energy passes directly through single crystal, which has obvious advantages in thermal conductivity. Our single crystal alumina product has high melting point, good stability, small specific surface area, clean surface, no residual metal impurities and burr, high sphericity, high α phase content, low surface oil absorption value, single crystal transparent, good viscosity reducing effect, excellent thermal conductivity and electrical insulation. It can be used in lithium battery ceramic diaphragm coating, thermal interface materials, thermal conductive engineering plastics, high thermal conductive aluminum coated copper plate, ceramic filter coating, etc.

Download documents

99.995% Alumina

High Purity Alumina manufactured by the improved Bayer process is widely used in high-end industries and cutting-edge science and technologies with its good chemical stability, high melting point, high mechanical strength, high hardness, good thermal conductivity and high insulation, such as new energy battery materials, sapphire, ruby, technical ceramics, ceramic substrate, spraying materials, photoelectric glass, semiconductor devices, insulators, power equipment manufacturing.

Download documents

99.9% Alumina

99.9% Alumina Powder has excellent electrical insulation properties, low loss tangent, high mechanical strength, satisfactory chemical stability and high temperature resistance, high thermal conductivity, good stability and high cost performance, which can be used as electronic ceramic substrates, insulating ceramics, Special raw materials for liquid crystal glass, cover glass, refractory materials, luminescent materials and other industries.

Download documents

Nano Alumina (Alumina Nano Powder)

This nano alumina has high purity and good particle size, and is suitable for ceramics, targets, refractory materials, catalyst carriers, lithium battery cathode materials, etc. This product is open for customize.

Download documents

High Purity Ultra-fine Alumina

High Purity Ultra-fine Alumina has the characteristics of high melting point, high hardness, good electrical insulation, wear resistance and high corrosion resistance. It is widely used in sapphire, surface coating for ternary materials of lithium battery, new energy materials, precision polishing, electronic ceramics, catalyst carrier, wear-resistant coating and other fields.

Download documents

High Purity Aluminum Hydroxide

High Purity Aluminum Hydroxide (Gibbsite) by the Bayer process, which appearances as white crystal powder, with uniform particle size, high purity, stable chemical properties, good crystal phase stability, and good sintering activity. High purity aluminum hydroxide is the excellent raw material for the preparation of optical glass additives and high-purity aluminum salts.

Download documents

High Purity Alumina Products

High purity alumina products include high Purity alumina granules, high purity alumina pellet, alumina crackle crystal and alumina polycrystalline. Our company produces 5N high purity alumina products with the advantages of high purity and density, which are mainly used for production large size sapphire crystals by Kyropoulos method, EFG method, TGT method and Czochralski method etc.

Download documents

Specialty Alumina for Fine Polishing

Specialty Alumina for Fine Polishing with moderate hardness, is more suitable for fine polishing. By selecting the right particle size products, and adjusting the solid content in the polishing liquid (1-60% adjustable), it will be achieved high cutting rates and fast light effect. For the same particle size product, the cutting rate will be increased obviously by improving the solid content in the polishing liquid. At present, our company has two series of products, GD and GDS. GD series are mainly used for the final polishing of mirrors of sapphire and others. GDS series are specially applied to automotive paint polishing, resin lens polishing, high-grade furniture paint polishing field.

Download documents

Feel free to contact us!

Contact us from the form below. Our staff will reply soon!

Here to ask about Alumina